Aluminum Precision Metal CNC Machining/Machined/Machine/Machinery CNC Lathe/Turning/Milling Parts for Auto

Basic Info.

| Model NO. | QJ- 001 |

| Certification | CE, RoHS, GS, ISO9001 |

| Standard | DIN, ASTM, GOST |

| Customized | Customized |

| Material | Aluminum |

| Application | Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Drawing Format | Powermill CAD Mastercam Creo Hypermill |

| Logo Service | Support |

| Tolerance | 0.001mm |

| Leadtime | Within 15 Days |

| MOQ | Prototype Is Acceptable |

| Inspection | Fqc, IQC, Pqc, Oqc |

| Machine Type | 5/4/3 Axis |

| Trade Terms | Fob/CIF /EXW |

| Surface Finish | Sandblasted/Anodized/Plated/Customized |

| Shipping Port | Shenzhen Port |

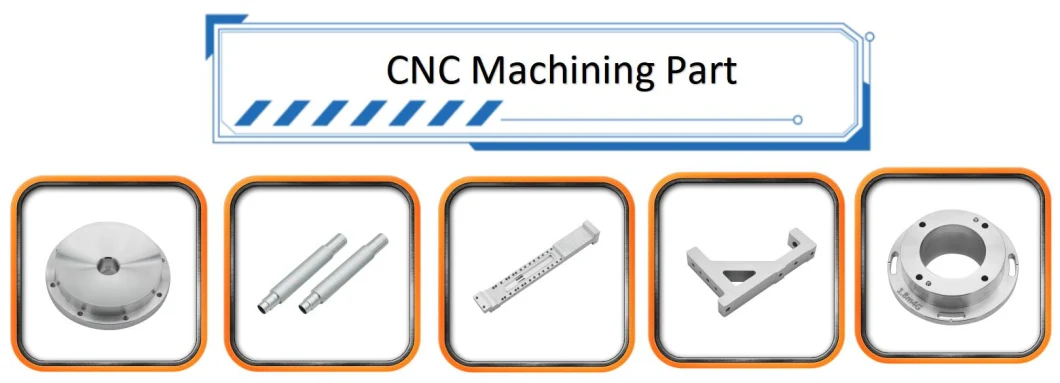

| Item | Machining Part, Turning Part, Milling Part, etc |

| Technics | Precision Machining |

| Supply | Drawing Design |

| Transport Package | Carton Boxes with Wooden Pallets |

| Specification | aluminum |

| Trademark | QJ |

| Origin | Dongguan, China |

| Production Capacity | 50000 Pieces/Year |

Packaging & Delivery

Package Size 45.37cm * 31.05cm * 29.30cm Package Gross Weight 20.000kgProduct Description

Our factory boasts a full line of 3/4/5 axis machining centers and automatic lathes, along with a range of testing tools, ensuring precision and accuracy in every product. With our 5 Axis CNC machining service, we offer a variety of CNC parts suitable for various industrial applications. Our team of experts is dedicated to providing high-quality products that meet your specific requirements. Trust us to deliver exceptional results every time. Choose our CNC Parts for your next project and experience the difference in quality and performance.

| Basic Info. of Our Customized CNC Machining Parts | |

| Quotation | According To Your Drawings or Samples. (Size, Material, Thickness, Processing Content And Required Technology, etc.) |

| Tolerance | +/-0.005 - 0.01mm |

| Surface Roughness | Ra0.2 - Ra3.2 |

| Materials Available | Ceramic,Tungsten,Aluminum, Copper, Brass, Stainless Steel, Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE etc. |

| Surface Treatment | Polishing, Surface Chamfering, Hardening and Tempering, Nickel plating, Chrome plating, zinc plating, Laser engraving, Sandblasting, Passivating, Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, etc. |

| Processing | Hot/Cold forging, Heat treatment, CNC Turning, Milling, Drilling and Tapping, Surface Treatment, Laser Cutting, Stamping, Die Casting, Injection Molding, etc. |

| Testing Equipment | Coordinate Measuring Machine (CMM) / Vernier Caliper/ / Automatic Height Gauge /Hardness Tester /Surface Roughness Teste/Run-out Instrument/Optical Projector, Micrometer/ Salt spray testing machine |

| Drawing Formats | Powermill CAD Mastercam Creo Hypermill |

| Our Advantages | 1.) 24 hours online service & quickly quote and delivery. |

| 2.) 100% quality inspection (with Quality Inspection Report) before delivery. All our products are manufactured under ISO 9001 | |

| 3.) A strong, professional and reliable technical team with 25+ years of manufacturing experience. | |

| 4.) We have stable supply chain partners, including raw material suppliers, bearing suppliers, forging plants, surface treatment plants, etc. | |

| 5.) We can provide customized assembly services for those customers who have assembly needs. | |

Our Capability

Material Capability

We cooperate with many high-quality material suppliers, the quality is very guaranteed, please rest assured to choose our materialsl. At the same time, all materials can provide certification documents. Material available, such as aluminum alloy, steel alloy, stainless steel, copper, brass, titanium, Bronze, Nylon, Acrylic etc. Alu 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze(H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEK etc. as customer's request.

Heat Treatment, Painting, Power Coating, Black Oxide, Silver/Gold plating, Electrolytic Polishing, Nitrided, Phosphating, Nickel/Zinc/Chrome/TiCN Plated, Anodizing, Polishing, Passivation, Sandblasting, Galvanizing, Heating Treatment, Harden, Laser mark etc. as customer requested.

Our Service

Our factory has been specialized in CNC machining for 15 years, equipped with the latest machines and tools and the professional team, we've offered the precise machining parts and services for many companies such as HUAWEI, ZTE, UBTECH, MOBI...

Dongguan QiJia Precision Technology Co., Ltd is a private enterprise which specializing in manufacturing high precision CNC machining parts, we offer custom CNC milling, CNC turning, CNC lathing, die casting and metal stamping service for worldwide customers.The facotry located in Dongguan - the manufacturing hub in China. With advanced facilities and well-skilled operators and engineers, we have provided thousands of OEM projects (custom CNC milled parts, good accuracy CNC milling and turning components) to our clients with good quality and fast delivery.

Application

Today, CNC machining is the leading manufacturing method in industrial applications, wide range of materials selection, various surface treatment options, high precision and tight tolerancesflexible scale of products, and rapid turnaround and less manual operations involved, all these make the complex CNC machining the tendency of in modern manufacturing industries such as aerospace, electronics, agriculture, and end-use products, etc.

Packaging & Shipping 1.We prefer DHL or TNT express or other air freight between 1kg-100kg. 2. We prefer sea freight more than 100kg or more than 1CBM 3. As per customized specifications.

1. Q: Are you trading company or manufacturer ?

A: We are direct factory with experienced engineers and employees as well as well-organized workshop.2

Q: How long is your delivery time?

A: Generally it takes 15-20 days based on your according to order quantity.3. Q: Do you provide samples ? Is it free or charged ?

A: Yes, we can provide the sample. The sample fee depends on the product complexity, and the fee will be returned when you place bulk order.4

Q: How long can I get the sample?

A: Depends on your part complexity, normally within 3-7 days.5. Q: What is your terms of payment ?

A: 30% T/T in advance, balance to be made before shipment.