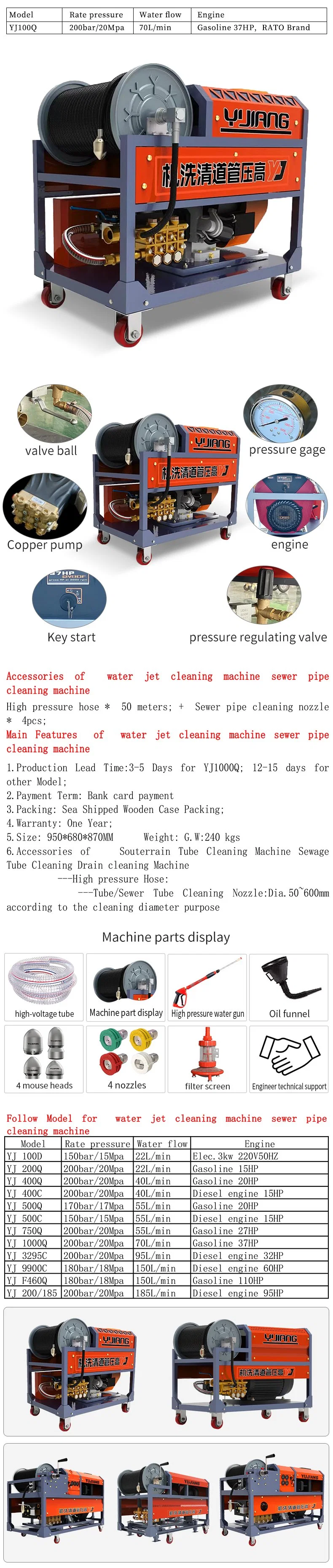

Pipeline Dredging Dredging High

tructions for use: 1. Put the high-pressure pipe with the nozzle installed into the sewer pipe, and the operator prompts;

Basic Info.

| Model NO. | YJ1000 |

| Structure | Piston Pump |

| Assembly | Booster Pump |

| Power | Gasoline Engine |

| Start Up | Electric Start |

| Type | Jet Pump |

| Application | Booster Cleaning Pump |

| Industry | Mechanical Pump |

| Media | Sewage Pumps |

| Performance | Explosion-Proof Pumps |

| Theory | Jet Pump |

| 3-Way Valve | Khb3K-G Type High Strength Wear-Resistant Stainles |

| The Whole Machine Process | Electrophoretic Paint, Automotive Technology |

| Reel System | Dyj Reinforced Type |

| Shock Absorber | Thd Standard Shock Absorption |

| Transport Package | Wooden Box |

| Specification | 1370*65*95 |

| Trademark | Yujiang |

| Origin | Hebei |

| Production Capacity | 560000 |

Product Description

1. Put the high-pressure pipe with the nozzle installed into the sewer pipe, and the operator prompts the personnel looking at the equipment to prepare to start the equipment.

2. New equipment or temperature below zero, the staff looking at the equipment need to pull the gasoline engine damper and start the equipment key (the middle is ready to ignite, the right side is the starting state, and the ignition time needs to be controlled)

3. Start the gasoline engine, adjust the throttle, and the throttle handle is recommended to increase the throttle.

4. Rotate and adjust the handle of the pressure regulating valve in the direction, adjust the working pressure of the high-pressure pump upward, and observe the pressure gauge to display the actual working pressure. After the pressure is stabilized, the sewer is dredged.

5. When cleaning and dredging the external pipeline, it is recommended to clean and dredge the operation from the downstream of the pipeline to the upstream, so that the cleaning dirt can be smoothly cleaned downstream, and at the same time, it is necessary to ensure that the downstream pipeline can discharge sewage normally.

6. During normal cleaning operations, the high-pressure pipeline dredge machine can coil and artificially shake the high-pressure pipe left and right, causing the pipeline nozzle to rotate and cut 360 degrees in the pipeline, which can be guaranteed

It is proved that the dirt on the inner wall of the pipeline can be evenly stressed. The high-pressure pipeline needs to enter the pipeline with pressure, and at the same time pull back with pressure (the 1.5-meter position of the pipe head needs to be marked, such as using a thin wire meal around 4 circles "to prevent the nozzle from pulling out the pipeline when pulling back, causing potential safety hazards). The nozzle is 40-50 cm away from the pipe mouth at a safe distance, and the cleaning and dredging effect is better. 7. During operation, operate back and forth about 4-6 times until the water discharged in the pipeline is clean water, which indicates that the sewer has been completed

Fully cleaned and unclogged (observing the surface of the high-pressure pipe or the sewage in the discharge pipeline can determine whether the pipeline is unclogged clean)

8. After cleaning and dredging, whether the equipment operation needs to rotate the pressure regulating valve handle in the opposite direction (left direction), adjust the actual pressure of the high-pressure pump, adjust the pressure to zero to observe the display value of the pressure gauge), and at the same time pull the gasoline engine throttle handle down, adjust the throttle handle to lower, relieve about 2 seconds, and switch the key switch to the left.

Resolution of common problems:

1.What is the material inside the pump ?

our pump head materials are all ceramic plungers with high strength and wear-resistant materials

2.Questions about shipping

Wooden boxes are packed and sent directly to the port

3.Warranty PrincipsOur machines are guaranteed for one year, except for consumable parts, "consumable parts include plunger pump water seals, oil seals, check valves, pressure regulating valves, filters, filter elements and other consumables"

You may also like

Send inquiry

Send now